In The News

Bucket Brake Plus

TM

__________________________________________

2003 Copyright Bucket Brake LLC

Dreaded job inspires handy new invention

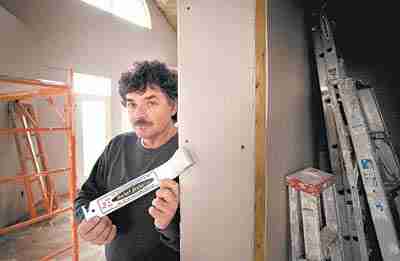

Drywaller Phil Roebuck of Virginia Beach spent two years perfecting the Bucket Brake Plus, a tool that can be used to break the seal on a large bucket, pry off the lid and then hold the bucket steady while its contents are being mixed.

By KRYS STEFANSKY, The Virginian-Pilot

Copyright January 29, 2004

VIRGINIA BEACH - Two years ago, in November, Phil Roebuck stood in front of six 5-gallon buckets of drywall mud.

He was about to tape the drywall and plaster over it in a house under construction. But, first, he had to open the buckets, then mix what was inside.

For the nearly 30 years he'd been in the drywall business, he'd always hated this part of his job.

He knew he wasn't alone. Tile guys used and dreaded these same buckets. Construction crews mixing quick-dry cement did, too.

"You have to cut the lids of the buckets with a utility knife," Roebuck said, "then pry the lids off with your fingers. It hurts your hands."

None of the cheap plastic openers he'd ever tried really worked.

It didn't get better. The mud inside has to be churned with a half-inch drill with paddle attachment - kind of a heavy-duty eggbeater. Turn on the drill and the bucket could whirl out of control, sending the handle flying right into a person's shinbones.

"Some people stand on top the bucket to keep it from spinning," he said. "But that's dangerous because your feet are usually wet."

That day, Roebuck took a deep breath. Then he looked around. Somebody had tossed a U-shaped metal joist hanger on the floor. He looked at the bracket. He looked at the six buckets.

Whoa!

"I saw it right in my mind," he recalled.

He grabbed the hoist hanger, cut off one arm of it, banged it with a hammer. put in a few bends.

He opened a bucket with his fingers, put one end of his metal creation over the handle, stepped on it, turned on the mixer and ... the darn thing held still.

Phil Roebuck, inventor of the Bucket Brake Plus.

"People see it now and say, 'Why didn't I think of that?" he said. "That's the kind of invention you want."

He'd had ideas before but had never acted quickly enough to make them his own. And competition among inventors is stiff. Of the 356,493 applications for patents received by the U.S. Patent and Trademark Office in 2002, only about half, or 184,379, were granted.

This time, the difference might have been the picture of Elliott, the Chihuahua. For several weeks before he had his inspiration, Roebuck had driven around with a picture of his dog propped in his truck. Elliott was seated on a white leather office chair in front of a stack of gold bricks.

Slowly Roebuck felt his way through the process from invention to marketable product.

He drove home in his red Toyota pickup that night - shins intact and Elliott's marble eyes sending vibes from the photo - logged onto the Internet and ordered a kit to set up a patent. He studied the laws explained in the kit and went to work on a prototype.

Back at the new house the next day, he scrounged around for another joist hanger, formed a rounded shape and tried that out.

A month later, he applied for and received a provisional patent.

Meanwhile, he worked on a name for his new tool and made a Plexiglas model.

That worked fine, Until it got cold. Then it broke.

He made another one, cushioned it with nonslip bathtub decals and a little rubber brake pad. Cute. Maybe too cute.

He crafted five prototypes in a year. His brother, Sam, a welder, helped form one from aircraft aluminum.

Too much, too big.

They made it smaller. Made it fit the hand.

Roebuck's fiancee, Kelly, looked at it one day and had a question: "Have you tried opening tops with it?"

Phil and Sam Roebuck made another model, this time with a cutting blade at one end.

"With this one, you could cut the lid, open it and stop the bucket from spinning." Roebuck said, "the whole works." No more sore fingers.

A year went by. Then another.

Roebuck worked on his project until late into the night and on weekends. He modified his tool so it would open paint buckets, too. He designed a label, and instruction sticker. He learned enough legalese to persuade the patent office to let him name his product.

He paid for the whole thing himself bit by bit - about a $16,000 investment.

"I didn't want to go into debt with it" he said. "I would just work hard, make a little extra and take another step."

The Bucket Brake Plus is manufactured in China now and has been on shelves and for sale on the Internet since August.

The patent is pending and due any day.

Roebuck loves reading e-mails about his invention.

"I got one from a distributor in Denmark," he said, pulling up the letter. "He said he wants information about my 'bucket braker tool.'"

He laughs about the remodeler in Missouri who reviewed his tool, loved it and told others online that it was "invented by a drywaller, but don't hold that against him."

Other eBay-ers have said it's "easy to use" and "a great product"

Local drywall and tile professionals are passing the word, too.

"I tell everybody," Bob Snyder said. The Virginia Beach drywall finisher has two Bucket Brakes. "I use one every single day I'm at work. It's one of those permanent fixtures in my bag. It's awesome."

Roebuck grinned and rested on his laurels for a minute.

"I love this stuff," he said.

Elliott knew it all along.

Copyright 2004 Bucket Brake LLC